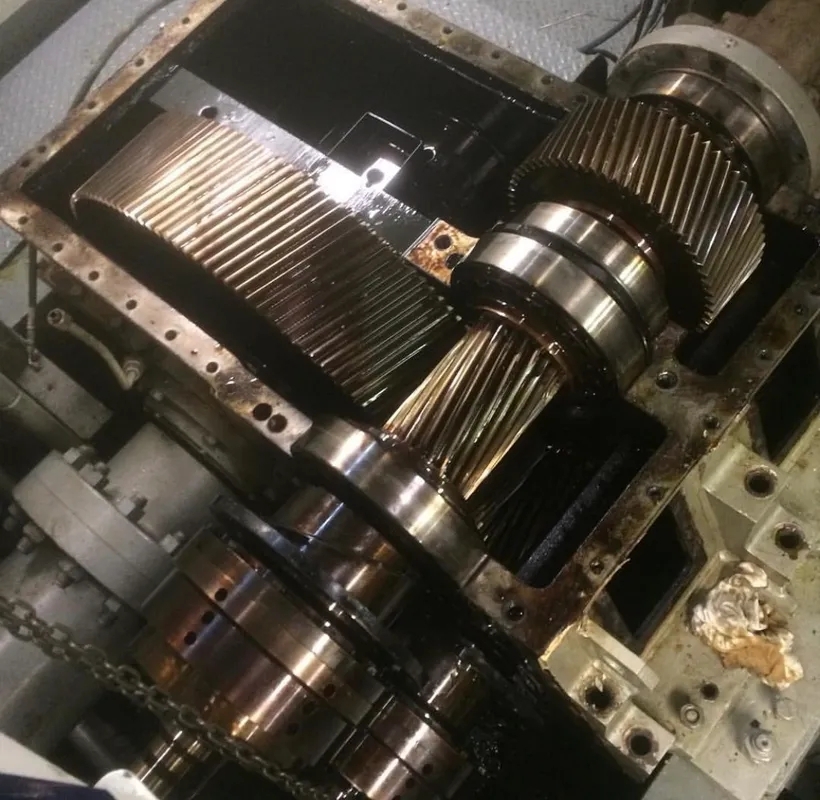

Gear Tooth Hardening Services

What is the process involved in gear tooth hardening services?

Gear tooth hardening services typically involve a process known as induction hardening, where a high-frequency electrical current is used to heat the surface of the gear tooth. This localized heating allows for rapid quenching, resulting in a hardened outer layer while maintaining a softer core. This process helps improve the wear resistance and overall durability of the gear teeth, making them suitable for demanding applications.

Specialized Industrial Gear Repair and Maintenance Solutions and Equipment