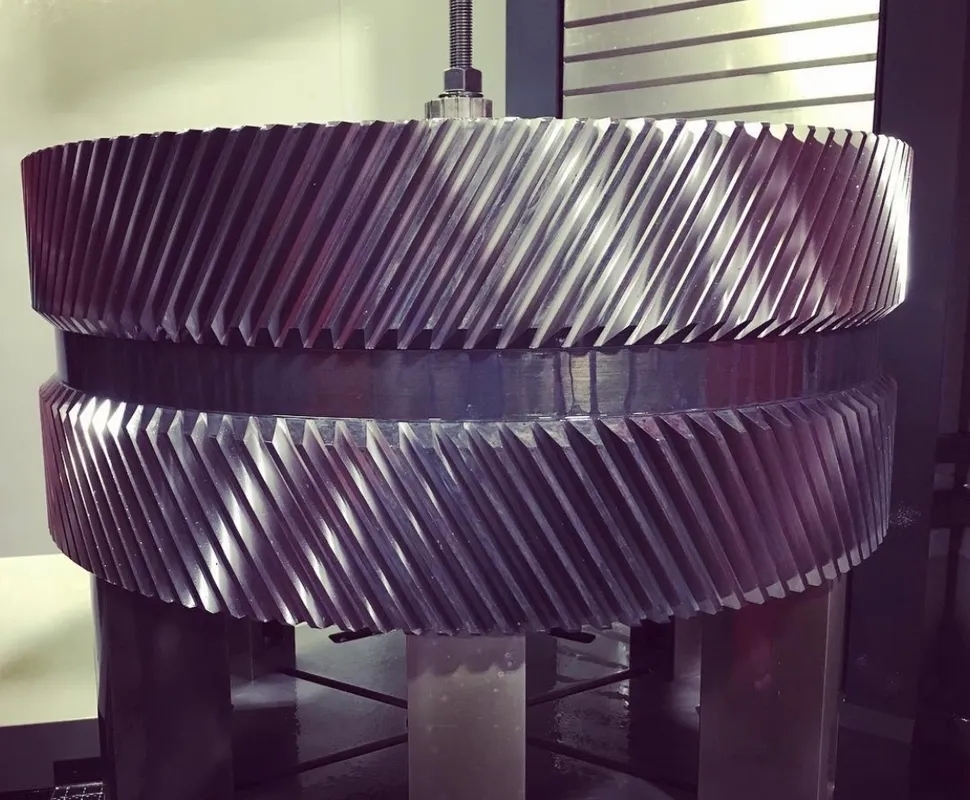

Gear Tooth Geometry Measurement

How is the involute profile of a gear tooth measured?

The involute profile of a gear tooth is typically measured using a gear tooth vernier caliper or a gear tooth micrometer. These specialized tools allow for precise measurements of the tooth profile, including the addendum, dedendum, and tooth thickness. By accurately measuring the involute profile, manufacturers can ensure proper gear meshing and smooth operation of the gear system.