Gear Noise Reduction

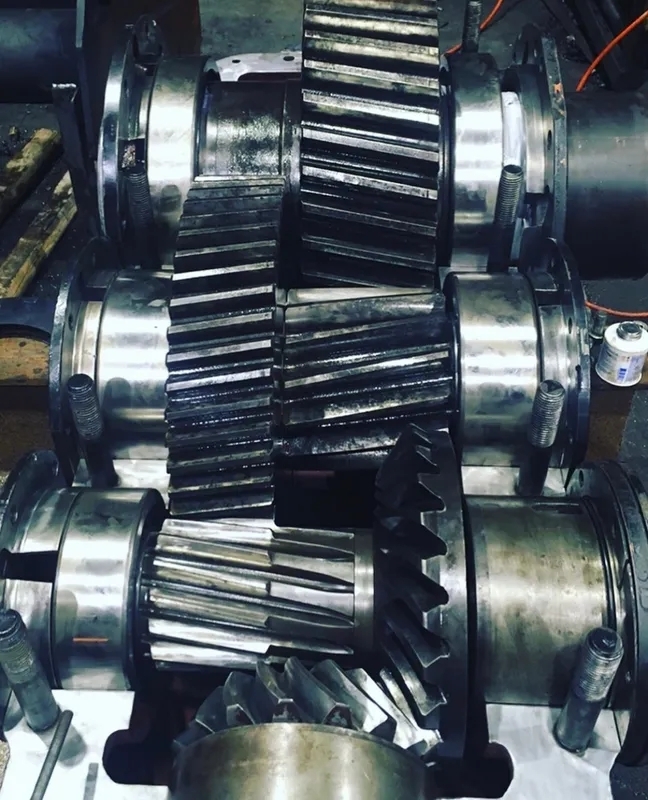

How can gear noise be reduced through the use of helical gears?

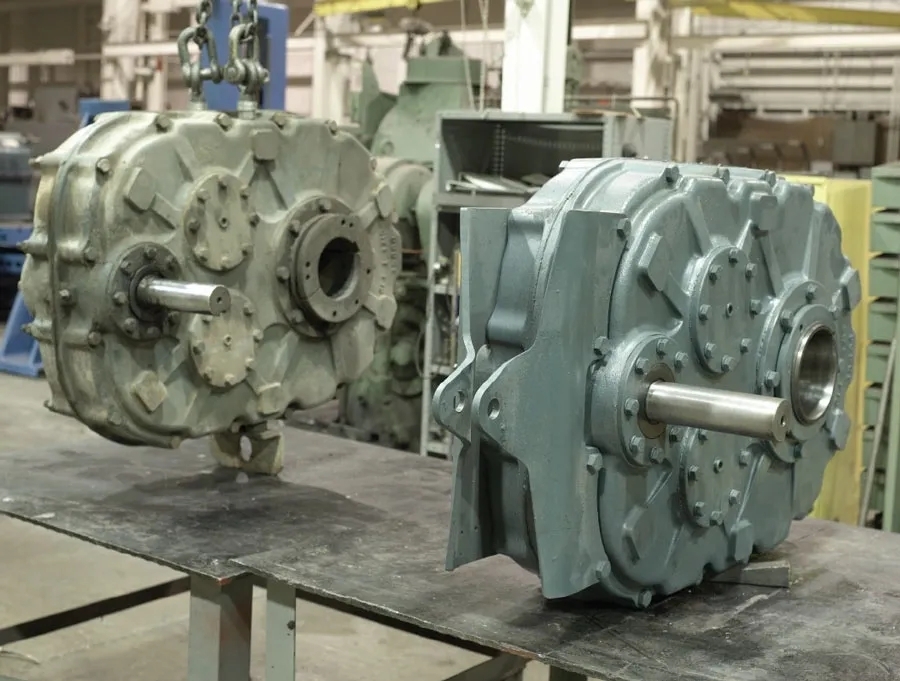

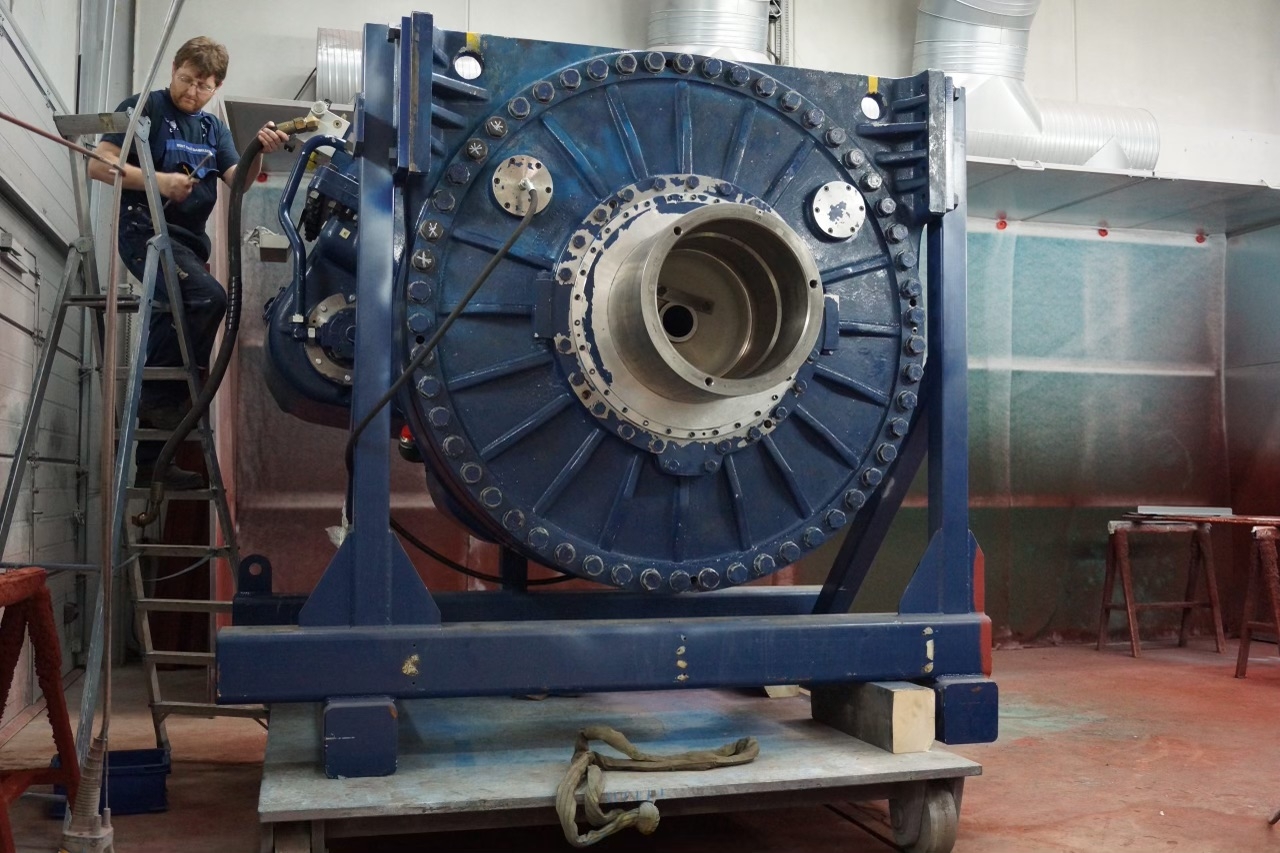

Helical gears are known for their ability to reduce gear noise due to their unique tooth geometry. The helix angle of the gear teeth helps to distribute the load more evenly across the teeth, resulting in smoother and quieter operation. The gradual engagement of the teeth in helical gears also helps to minimize impact and vibration, further reducing noise levels during operation.