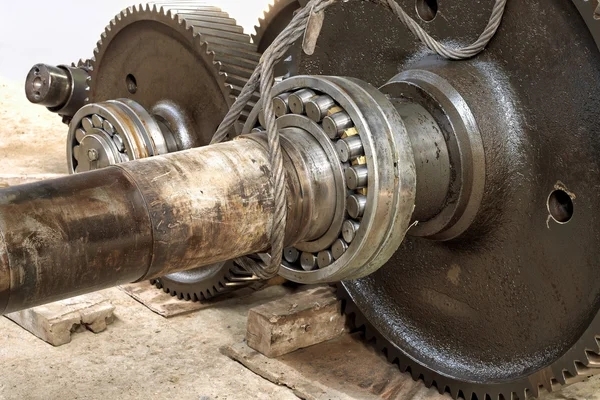

Gear Tooth Crack Detection

How can gear tooth cracks be detected using non-destructive testing methods?

Gear tooth cracks can be detected using non-destructive testing methods such as magnetic particle inspection, dye penetrant testing, and eddy current testing. Magnetic particle inspection involves applying a magnetic field to the gear tooth surface and then applying iron particles that will accumulate at the crack location, making it visible under UV light. Dye penetrant testing involves applying a colored dye to the gear tooth surface, which seeps into any cracks present and is then wiped off, leaving the dye only in the cracks. Eddy current testing uses electromagnetic induction to detect surface and near-surface cracks in the gear tooth.