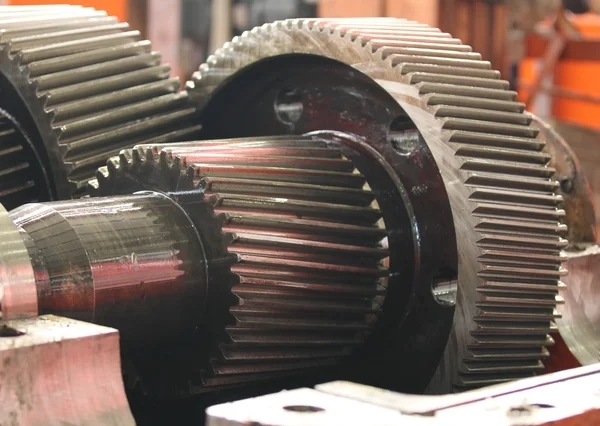

Gear tooth flank wear patterns can vary significantly across different industrial applications due to factors such as load distribution, lubrication methods, operating speeds, and material properties. In high-speed applications such as aerospace or automotive industries, abrasive wear may be more prevalent due to the increased friction and heat generated during operation. In contrast, in heavy machinery or mining applications, adhesive wear may be more common due to the high loads and pressures involved. Additionally, the type of lubrication used, whether it be oil, grease, or dry lubricants, can also impact the wear patterns observed on gear tooth flanks. The material composition of the gears themselves, such as steel, cast iron, or composites, can further influence the wear mechanisms experienced in different industrial settings. Overall, understanding the specific wear patterns in a given application is crucial for optimizing gear performance and longevity.