Gear Performance Optimization

How can gear performance be optimized for high-speed applications?

Gear performance can be optimized for high-speed applications by utilizing precision machining techniques, such as grinding and honing, to ensure accurate tooth profiles and minimal runout. Additionally, selecting high-quality materials with excellent strength and wear resistance, such as alloy steels or titanium alloys, can enhance performance under high-speed conditions. Proper lubrication is also crucial to reduce friction and wear, allowing gears to operate smoothly at elevated speeds without overheating or premature failure.

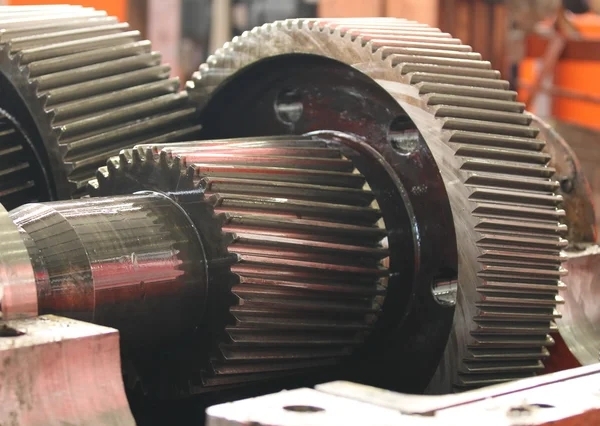

Specialized Industrial Gear Repair and Maintenance Solutions and Equipment